6006 Automatic Conveyor Switch

The automatic conveyor switch operates like the standard automatic switch. The automatic mechanism operates either above the conveyor chain or to one side-out of the way. All switching time is saved and there is no delay in feeding the conveyor. The conveyor chain cannot come in contact with any part of the switch. Available zinc plated or stainless steel.

Read More

6006 Heavy Duty Cut Thru Switch

The LeFiell cut-thru switch construction provides freedom from manual switching at any point where tracks must cross at right angles. This switch has interconnected pivoted track sections which are automatically lined up by a trolley moving in either direction on either of the two tracks. No operating handle is needed. The switch is completely automatic. With this switch there are no open track ends. Available zinc plated or stainless steel.

Read More

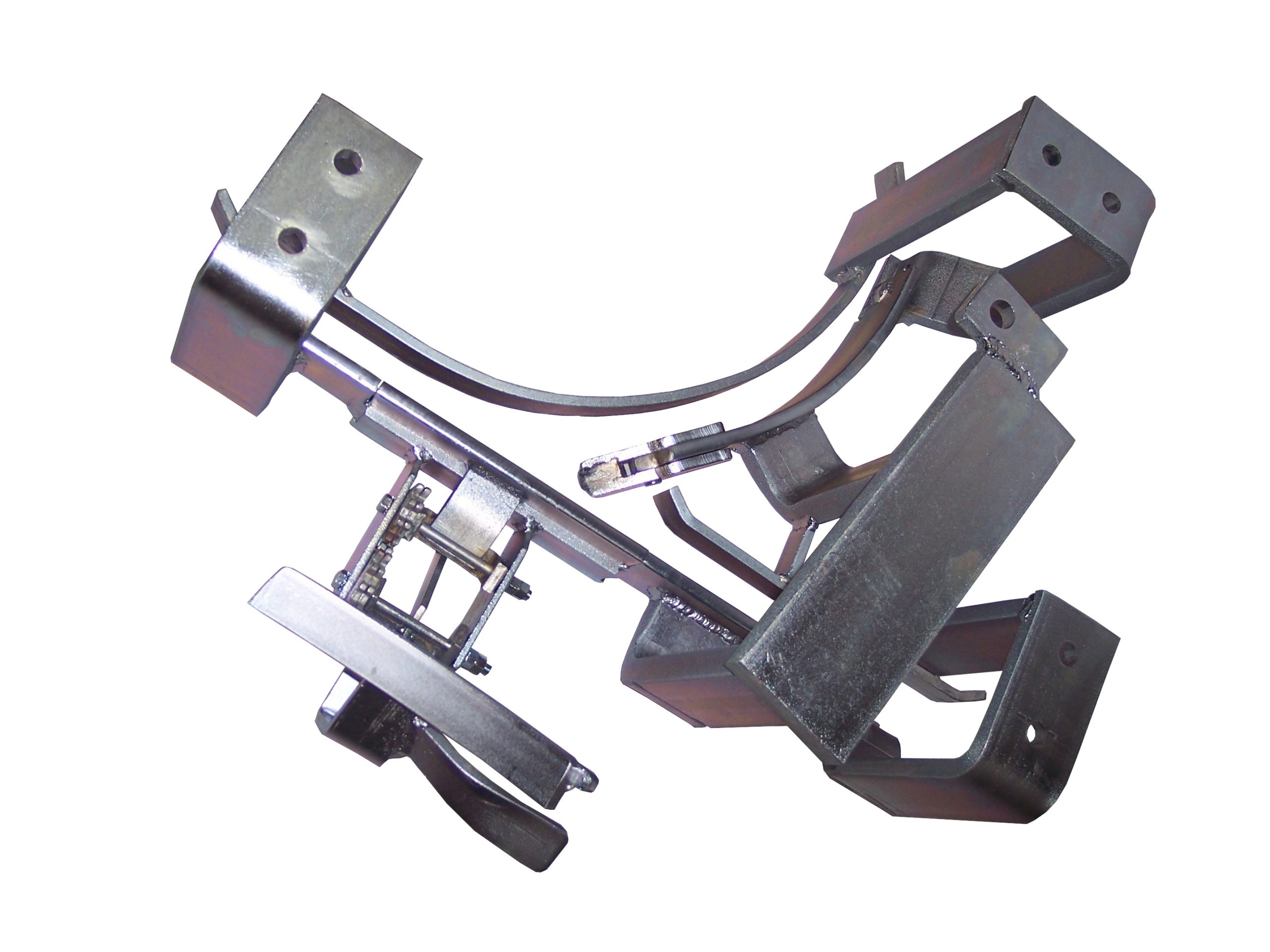

6006 Standard Automatic Switch

500 lb. capcity. The LeFiell automatic switch eliminates manual operation in gathering to a common head rail from the "C" or "I" ends of the switch. The weight of the forward motion of an approaching load along either rail actuates the switch closing one rail and opening the other. A direction selector option added to this switch enables the operator to select and hold the switch in either selected direction without interfering with automatic operation - thus back switching is automatic and accomplished without touching the switch. Available in zinc plated finish or stainless steel.

Read More

6007 Gear Operated Switch

The LeFiell gear operated switch features a positive actuation of the double lift. This is accomplished through the use of steel gears. An outstanding advantage of this switch is the ease and simplicity with which it may be installed the fact that it is virtually maintenance free. This is the 1500 lb. capacity model. Available zinc plated or stainless steel.

Read More

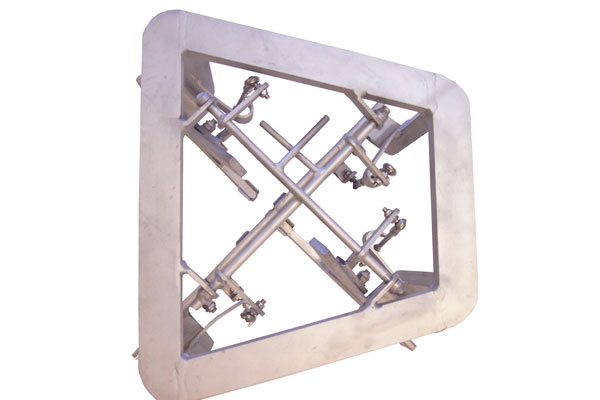

6006 Standard Cut Thru Switch

The LeFiell cut-thru switch construction provides freedom from manual switching at any point where tracks must cross at right angles. This switch has interconnected pivoted track sections which are automatically lined up by a trolley moving in either direction on either of the two tracks. No operating handle is needed, the switch is completely automatic. With this switch there are no open track ends. Available in standard 500 lb. and heavy duty 1500 lb. capacities. Available zinc plated or stainless steel.

Read More

6007 Standard Gear Switch

500 lb. capacity. Features positive actuation of the double lift. Simplicity of installation and maintenance make this a popular switch in the maintenance department. Available in zinc plated finish or stainless steel.

Read More

6008 Auto Bleed Rail Switch

Constructed of high carbon plow steel for toughness and durability. Specially designed for use when rail coverage or back switching is required. Has the same features as the No. 6006. Available for use with 1/2" x 3" or 5/8" x 3" track with 13" or longer hangers. Specify rail and hanger size. Air operated remote control attachment available on all bleeding rail switches for complete control at the most convenient point.

Read More

6008 Gear Bleed Rail Switch

3,000 lb. capacity. The LeFiell gear operated bleeding rail switch features a positive actuation of the double lift. This is accomplished through the use of steel gears. This extra heavy duty bleeding rail switch has all the benefits of the model 6007 gear operated switch with the extra weight capacity for a full carcass load or heavy racks in further processing. Available zinc plated or stainless steel.

Read More.jpg)

6009 SST Automatic Conveyor

This is the next generation of overhead track switches. It has been designed to provide better durability, performance, longevity and ease of maintenance. The SST stands for "Short Section Track" referring to the shorter lift section on SST. This means that trolleys spend less time on the spans, which reduces the chance of temporary or permanent horizontal deflection. The SST also has a redesigned pivot connection that evenly distributes bearing surface pressures, reducing the chance of warping. The SST eliminates off-center landings with thick steel vertical locator guide tabs at both ends of the intersection point of the switch. When it comes to maintenance, the SST and its fully adjustable tie rods make adjustments a piece of cake. The SST's tie rod bushings are metal-to-metal and are less susceptible than nylon bushings to the heat and cold degradation that can commonly occur in meat plants. The direction selector on the SST is mounted out of the way on the side of the upright yoke, not on the pivot/axle bolt that forces it to hang several inches below the meat rail.

SST SWITCH OPTIONS:

Saf-T-Guard guard rail to prevent trolley drop-off

Similar models available for loads of 500 lb. and 2,500 lb.

Fully automatic operation with hydraulic or pneumatic cylinders and control panel available upon request

Manufactured level or "C" end up or down 2-1/2

Stainless steel